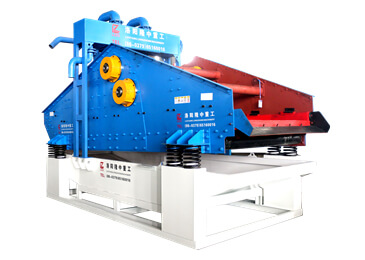

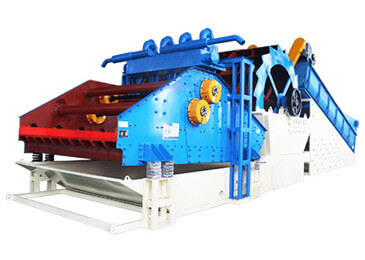

Silica sand production equipment includes a vibrating feeder, jaw crusher, sand making machine, vibrating screen, belt conveyor, and sand washing machine. According to different process requirements, various types of equipment are combined to meet the different process requirements of customers.

Silica sand is a hard, wear-resistant, and chemically stable silicate mineral. It is a non-metallic mineral, and its main mineral component is SiO2. The color of silica sand is milky white, or colorless and translucent, and is an important industrial mineral raw material. It is widely used in glass, casting, ceramics and refractory materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemical industry, plastics, rubber, abrasives, and other industries.

The silica sand production methods are mainly divided into dry production and wet production. Dry production uses no water, saves energy, no dust pollution, low iron content in the product, and small floor space. Wet production has a high yield.

The dry silica sand production method is crushing-separation-rough selection-selection-wind separation-dust collection, etc., that is, the quartz stone is introduced from one end of the equipment, and the other end can produce qualified products of various specifications. The bagging is done at one time.

The kind of silica sand is mainly used in the manufacture of glass, refractory materials, ferrosilicon smelting, metallurgical flux, ceramics, abrasive materials, casting, etc. It is used in construction to have a strong resistance to acid media to produce acid-resistant concrete and acid-resistant mortar.

The wet processing technology is often used by new and large processing companies. It has the advantages of uniform product size, over-grinding, and fewer large particles. Typical process: raw ore-crushing-wet rod mill-fine screening (removing coarse particles)-hydraulic classification (removing fine particles)–magnetic separation and iron removal- —Dehydration, and its degree of mechanization is relatively high.

First, the stone material is initially crushed by the coarse crusher, and then the coarse material produced is transported by the belt conveyor to the fine crusher for further crushing. The finely crushed stone material enters the vibrating screen to screen out two kinds of stones to meet the feeding size The pebbles are filled with machine-made sand, and the other part is returned to be finely broken. Part of the stones in the sanding machine is made into the sand, which is cleaned by the sand washing machine (optional) to make finished sand, and the other part is broken again by the sanding machine.

The silica sand production line has a high degree of automation, low operating cost, high crushing rate, energy saving, large output, low pollution, easy maintenance, and the machine-made sand produced meets the national construction sand standard, with uniform product size, good grain shape, and reasonable gradation.

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-18736301510