With the shortage and non-renewable of mining resources, LZZG blockbuster launched DS series new sand washing equipment. It is widely used for crushed sand, river sand, lake sand or sea sand washing, screening, recycling and dewatering.

LZZG series introduced products to absorb foreign advanced technology, and designed combined with sand field actual situation. It can effectively reduce the loss amounts of fine material; solve problems of end product such as relatively high fineness modulus and relatively low stone powder content. The fine material can be recycled as high as 95%, with incomparable technical and economic advantages.

| Model | Feeding Size (mm) | Capacity (t/h) | Spiral Diameter (mm) | Impeller Diameter (mm) | Screen Panel (mm) | Hydrocyclone(mm) | Power (kw) | Overall Size (mm) |

| DS40 | ≤10 | 20-40 | 760 | 1800X800 | 1200X2400 | 300X2 | 48.4 | 11900X5250X3880 |

| DS60 | ≤10 | 30-60 | 920 | 2600X1200 | 1500X3000 | 300X2 | 55 | 14550X5560X4150 |

| DS80 | ≤10 | 40-80 | 1120 | 3000X1600 | 1800X4200 | 300X4 | 95 | 16250X6200X3700 |

| DS100 | ≤10 | 60-100 | 920X2 | 3000X1600 | 1800X4200 | 300X4 | 110.5 | 16250X6200X3700 |

| DS150 | ≤10 | 100-150 | 1120X2 | 3600X2000 | 2400X4200 | 350X4 | 140.5 | 17450X6800X3700 |

| DS160 | ≤10 | 100-160 | 1120X2 | 3600X2400 | 3000X4800 | 300X6 | 168 | 18000X7400X4260 |

| DS200 | ≤10 | 120-200 | 1500X2 | 3600X2400 | 3000X4800 | 350X6 | 196 | 18000X7400X4600 |

| DS250 | ≤10 | 160-250 | 1500X2 | 4200X3000 | 3600X6000 | 350X6 | 214 | 18580X8000X5200 |

Modular wash plant as a piece of representative equipment that combines multiple washing, coarse and fine materials concentrated dewatering, fine sand recycling, and other functions in one equipment. It is applicable to sand and gravel plants, construction sites, hydropower dams, glass manufacturing, oil well development, and other industries. Compared with the washing and recycling machine, it has been greatly improved in performance.

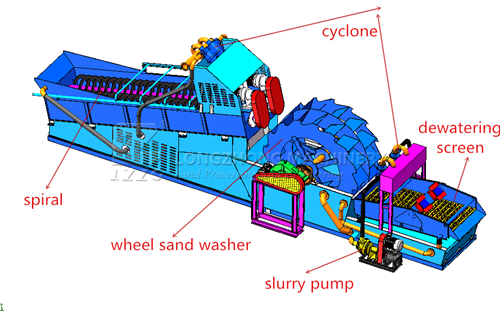

Working principle

Working principle

The qualified materials after classified by screening equipment flow into the screw sand washer through a chute or pipeline. Sand and gravel are fully separated from impurities and mud through the fully cleaned, soaked, and broken by screw mixer. Fine sand and muddy water are deposited in the tail of the sand screw, and the fine sand is recovered through a cyclone separator. Then the coarse and fine sand enters the wheel sand washer machine at the same time for secondary cleaning to achieve complete separation of sediment. The coarse sand is lifted onto the high-frequency dewatering sieve by the impeller of wheel sand washer, the overflow muddy water flows into the dewatering screen water tank and concentrated by cyclone separator, and is dehydrated by the vibration of the screen to finally realize the cleaning, recovery, dehydration and dry heap discharge of gravel.

Features

1. Energy energy saving and environmental protection are the major themes of multi-functional sand washers. Functions include sand washing, fine sand recovery, dehydration and de-sludge, concentration, and classification, which can effectively remove sand impurities and obtain high-quality sandstone products with clean and low water content.

2. Multiple functions, reasonable structure, easy operation.

5 common faults of sand washing machinesThe sand washing machine is indispensable production equipment in the mechanism …

What are the factors of sand-making machine vibrationThe rotor is the core component of the impact sand-making machine. After the rot…

How to improve the sand production efficiency of the river pebble sand-making machineThe river pebble sand making machine is an important piece of equipment for sand…

What are the advantages of environmentally friendly sand-making machinesAs the main force for expanding molding sand sources, machine-made sand has ushe…

We pride ourselves in our commitment and the level of service offered and aim to work closely with customers, to ensure we meet your expectations. Our objective is to keep your business operations running as smoothly as possible on a day-to-day basis.

If you need the latest price list, please leave us a message here! We guarantee that your information will not be divulged to the third parties, and we will reply to you within one working day, thank you.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-18736301510