Answer: First of all, we need to determine the solid content of the sewage. The solids content is the proportion of solids contained in the sewage. In addition, we also need to determine the amount of sewage generated every day and the working time, calculate the processing capacity required by the filter press and then determine the volume and filtration area of ?? the filter press so that the appropriate filter press can be easily selected.

Taking a box filter press as an example, if it processes 100 cubic meters of sewage per hour and the solid content is 8%, a filter press with a filter chamber volume of 8 cubic meters is required, and a filter press with a filter area of ?? 500 square meters can be selected.

Answer: The filter press can realize the solid-liquid separation of the sludge. Generally, the moisture content of the sludge before entering the filter press is above 90%. After the filter press treatment, the moisture content of the filter cake can be reduced to 30%-60%. , can be shipped directly. According to the different materials, before entering the filter press, add appropriate flocculant to the material to cohere the solid substances together, thereby speeding up the filtration speed and improving the filtration effect.

Answer: Start the hydraulic station before filtration, and push the pressure plate to press the filter plate by the oil cylinder. After the pressure reaches the rated value, the hydraulic station will stop automatically, and then start the mud pump to transport the material to the filter press. The mud enters the filter chamber composed of the adjacent filter plates through the feed hole. Under the action of pressure, the solid particles are intercepted by the filter cloth in the filter chamber to form a filter cake with low moisture content, and the filtrate passes through the medium and is discharged from the filter plate. outside.

Answer: The service life of the filter cloth is generally 3-6 months. To ensure the filtering effect and prolong the service life of the filter cloth, when the filter cloth is not used for a long time, the filter cloth should be cleaned, dried, and stored in a dry place, and the folding should be avoided as much as possible. When the filter press is used frequently, if the filter cloth is found to be damaged, it should be replaced in time.

Answer: Filter cloth, faucet, and sealing ring are relatively common wearing parts, which can be replaced in time according to the usage.

Answer: There are three ways. First, remove the filter cloth from the filter plate, soak it in water and gently brush off the sundries on the surface with a brush. Second, use a high-pressure water gun to clean the filter cloth. Third, use the automatic cleaning device dedicated to the filter press to clean the filter cloth.

Answer: (1) The newly purchased filter press can only work after it has been debugged by professional technicians.

(2) Check the filter cloth and filter plate before starting the operation. The filter cloth should avoid folding, and the filter plate should be complete and flawless. It is forbidden to start the machine when the number of filter plates is less than the specified number.

(3) The filtration pressure should be guaranteed to be within the specified range, and the material concentration should be uniform, to achieve a better filtration effect.

(4) After the work is completed, the feed pump must be turned off before the filter plate can be depressurized and unloaded by pulling the plate.

Answer: (1) The installation position of the distributor is too high, and the position of the distributor cannot be adjusted.

(2) The distributor is partially blocked, resulting in the uneven spread of the cloth, and the blockage needs to be removed.

(3) The local wear of the mud rake is serious, which greatly reduces the water filtering effect of the local sludge. After entering the pressing area, it still shows strong fluidity, and the damaged mud rake needs to be replaced in time.

(4) The uneven wear of the reverse wiper plate is wavy, resulting in an uneven thickness of the mud in the area, which needs to be replaced.

If you have any unlisted filter press questions, please leave a message for a consultation!

Previous:Common fault analysis and treatment methods of sand making machine

Next:none

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

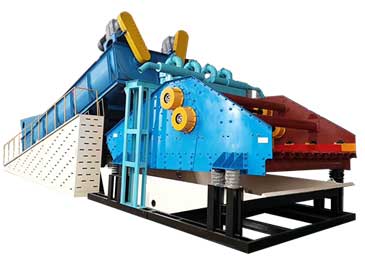

The latest sand washer price.

Installation and maintenance.

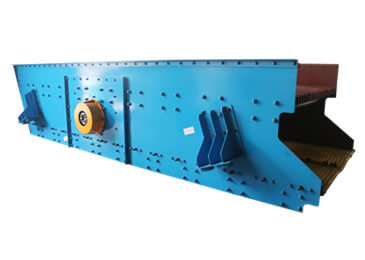

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-18736301510