Washed sand is raw sand for a foundry that is washed and graded with natural silica sand, with mud content (mass fraction) ≤ 1.0%. River sand is mainly floodplain sedimentary sand, which has a grayish-gray-yellow appearance, and contains medium-fine sand, medium-coarse sand, coarse sand, gravel layer, and gravel layer. Its occurrence is oriented towards the river bed, and the surface layer is inclined from the river bank to the river bed, inclined from upstream to downstream. The apparent density of river sand is 2580kg/m3, the bulk density is 1569kg/m3, and the fineness modulus is 2.89. It is medium sand. Mud content: 1.34%, hard texture, clear color, is a good building material.

Silo, vibrating feeder, crusher, sand washing machine, fine sand recovery machine, vibrating screen, and other equipment.

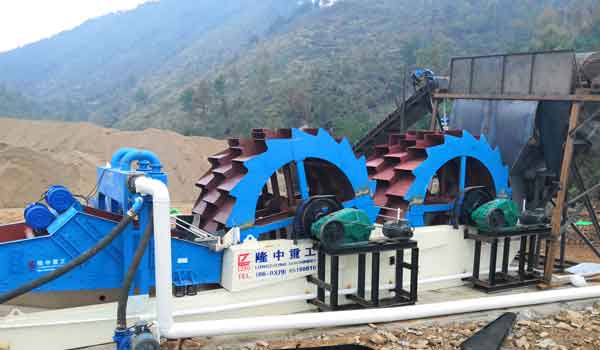

In this sand washing process, the sand washing machine used is a wheel sand washing machine. The wheel sand washing machine is also called an impeller sand washing machine. It is a bucket-type sand washing equipment used with the sand making machine and is a complete mechanism. It is an important piece of equipment for the sand and natural sand washing operations. It can wash away trace stone powder and impurities in the mixed sand produced by the sand making mechanism and improve the quality of the sand. The sand washing equipment adopts advanced technology and is developed in accordance with the actual situation of the sand and gravel industry. It is mainly used for the washing, grading, and dewatering of construction sites, sand and gravel plants, concrete precast plants of hydropower stations, glass plants, and pressure sand for backfilling oil wells.

Sand washing process of wheel sand washing machine

The sand in the bucket sand washer is continuously stirred, kneaded, collided and friction with each other through the rotating auger, so as to destroy the water vapor layer covering the sand and remove the impurities covering the surface of the sand. Then the sand is continuously pushed by the auger and finally discharged from the discharge end of the sand washing machine. In order to better clean the sand to reach the mud content specified by the national standard, the sand washer manufacturer uses two series-connected bucket sand washer to carry out long-term mixing, rubbing, and friction cleaning operations on the sand. The water vapor layer on the sand surface after being cleaned by the two bucket sand washing machines has been destroyed, and most of it has been discharged with the sewage.

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-18736301510